HOTT ProFormer

The ProFormer 12 is the most rigid, most advanced and highest performing curving canter profiling system on the market for processing up to 12 inch cants. The ProFormer consists of counter rotating dual head canters and vertical axes to equalize cutting forces on the center of the cant. The variable profiling heads can achieve vertically slewed sideboard solutions that competitor pocket profilers cannot provide. Coupled with the ProScission it is simply the best secondary breakdown solution available in the industry.

HOTT (Hanging-Over-The-Top) TECHNOLOGY

- Minimal footprint that typically fits into the existing Gang Infeed Module

- Rigid structure for maximum machine stability and accuracy

- Close coupling of Infeed and Mid-feed Press Rolls provides superior cant stability through the Canter/Profiler and into the Gang Sawbox

- Innovative design allows plumbing, cables and “moving parts” to be located out of the main debris area. This results in reduced maintenance requirements for such items such as linear bearings and cam followers while also reducing the risk of electrical cable and plumbing failures

- Easy machine access and built-in service lights for routine inspections, knife changes and maintenance

- Reduced cleanup and easier path for chips/debris to waste conveyors

double canter head design

- Does not influence cant path

- Vertically slewed profiled board solutions

- Press Rolls set to cant thickness

- Canter sets vertically to center of cant thickness

curve profiling

- +/- 6 degrees of skew with Canter Profiler Heads

- Profilers pivot independently of Canter to accurately follow curve path

- Currently running 200′ curve radius on curve thicknesses

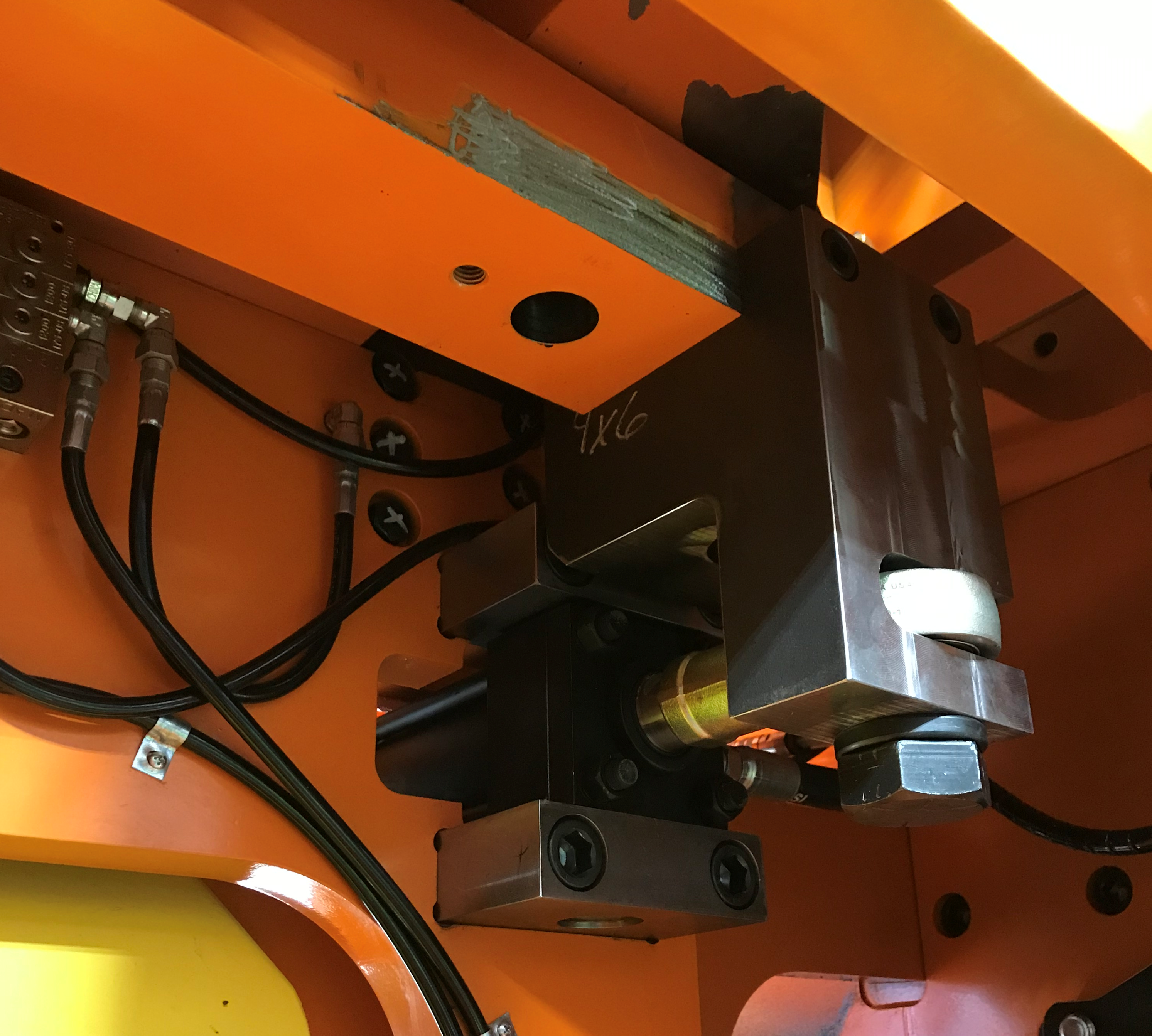

quick alignment checks

- Alignment Pins installed for all axes

- Easy to use “Go To Home” function to verify machine alignment

- Simple alignment check of Canter Slew and Skew using air cylinder actuated alignment pins and pin detection sensors

- Alignment check of other Profiler axes using manual “pin drop” locators

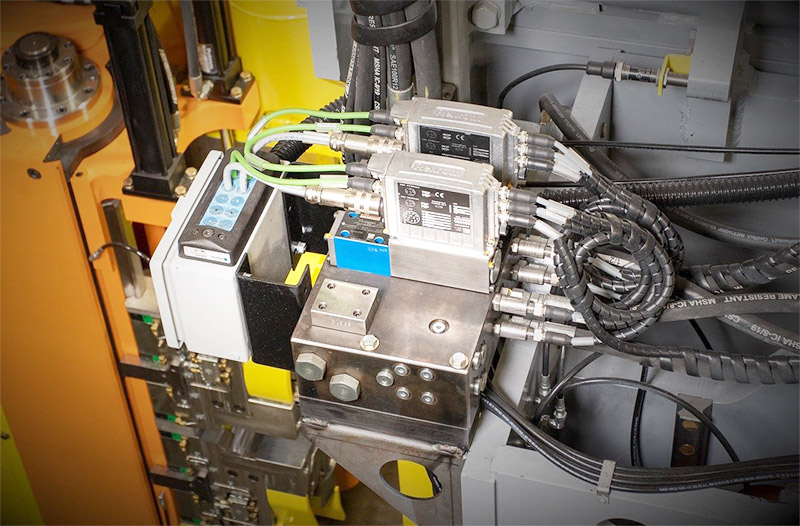

fully prewired & factory tested

- On-board I/O Enclosure with all devices factory prewired and functionally tested

- Ethernet Valave technology allows for factory tested axis prewiring to remain in-place during shipping which reduces on-site commissioning time

- Simplifies on-site electrical installation process