HOTT ProCanter

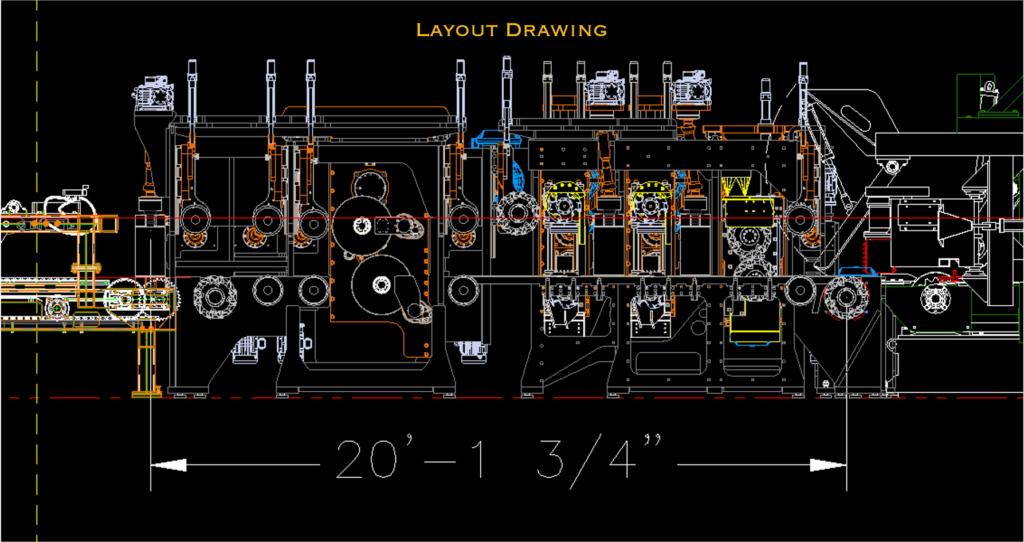

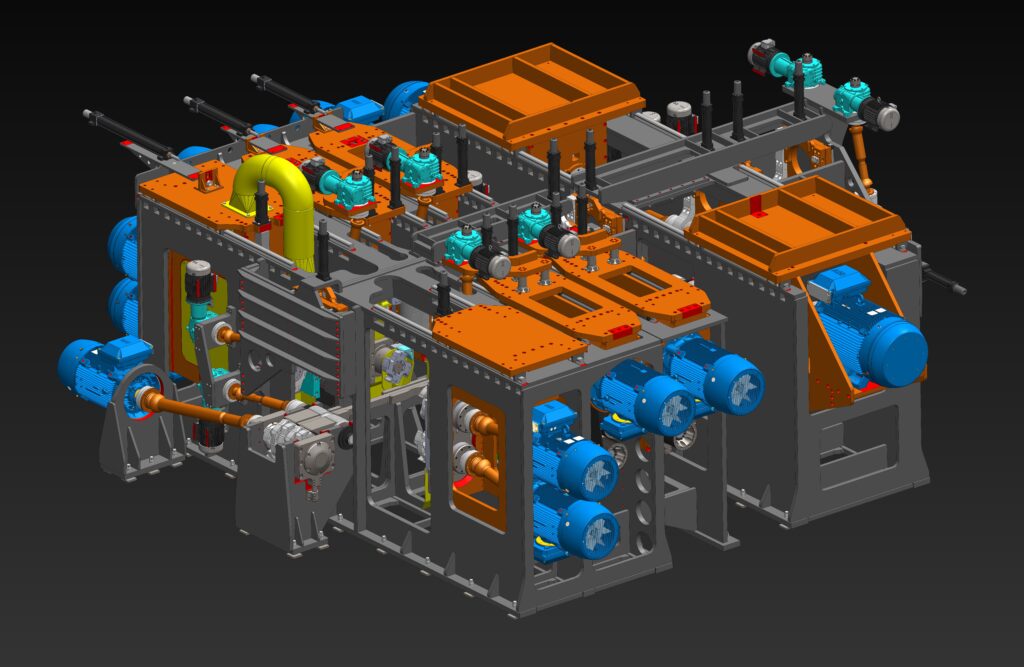

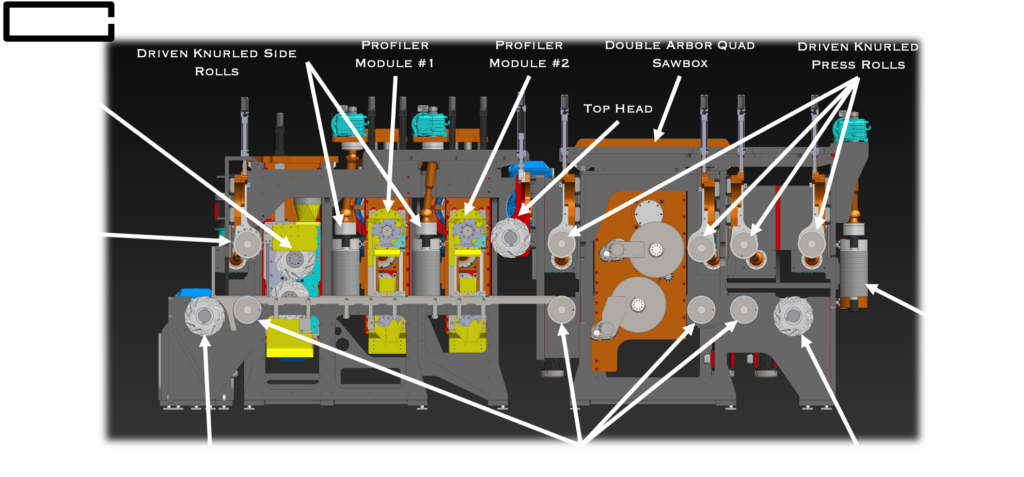

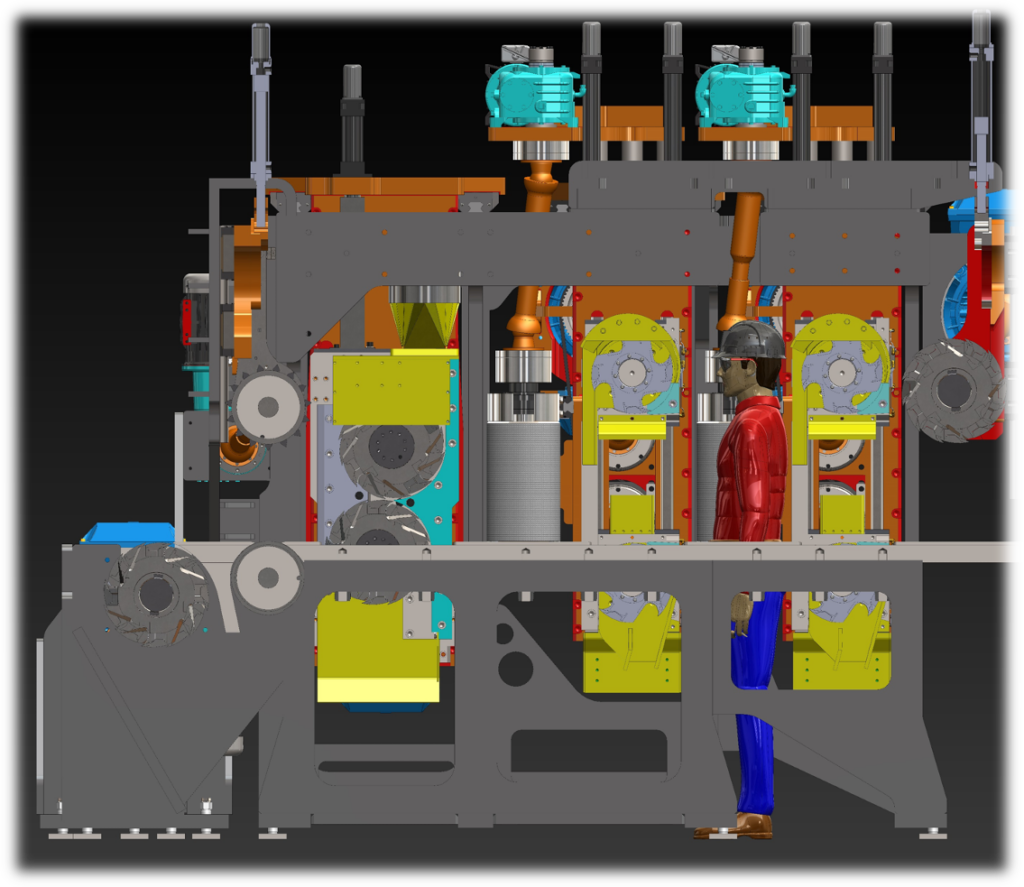

The ProCanter is a compact primary break down solution with double profiling that fits in the same footprint as a standard chip-n-saw line. No need to move VSA or other downstream equipment. With 15 driven rolls versus 8 on other existing systems we have superior control of the blocks being processed. Improve quality and overall mill flow due to reduction of edger loading from profiling on the ProCanter. As with all of our HOTT Technology systems, all critical components are located above the cutting tools and debris.

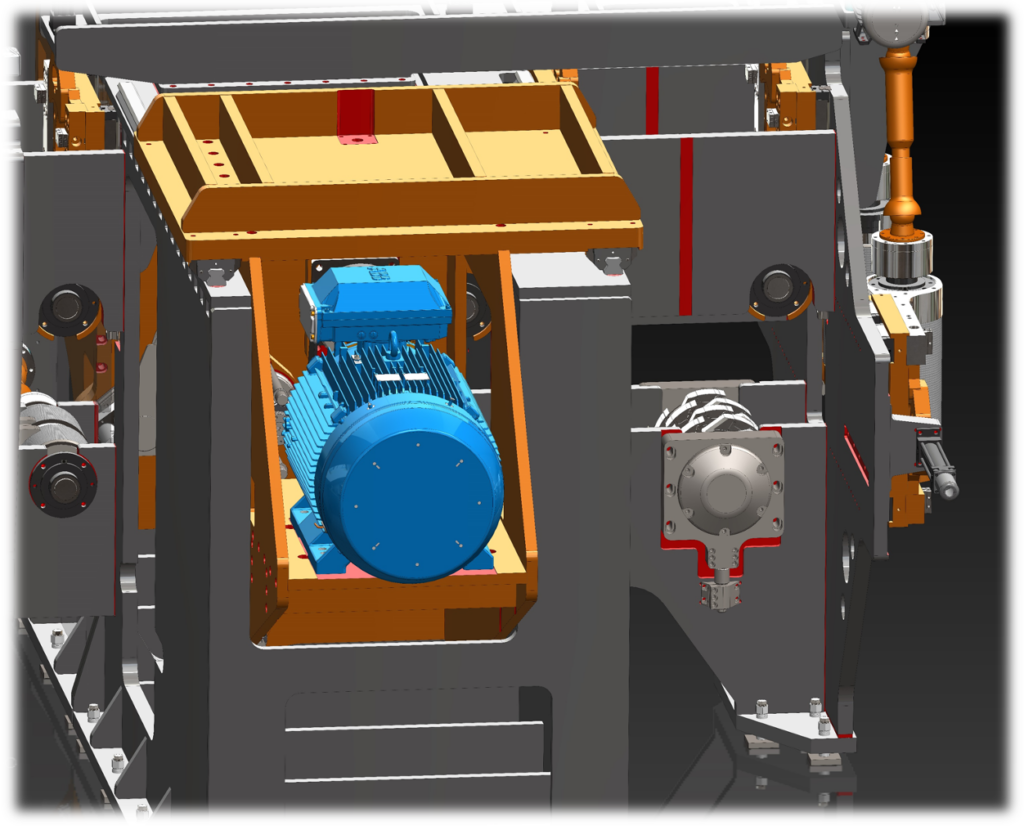

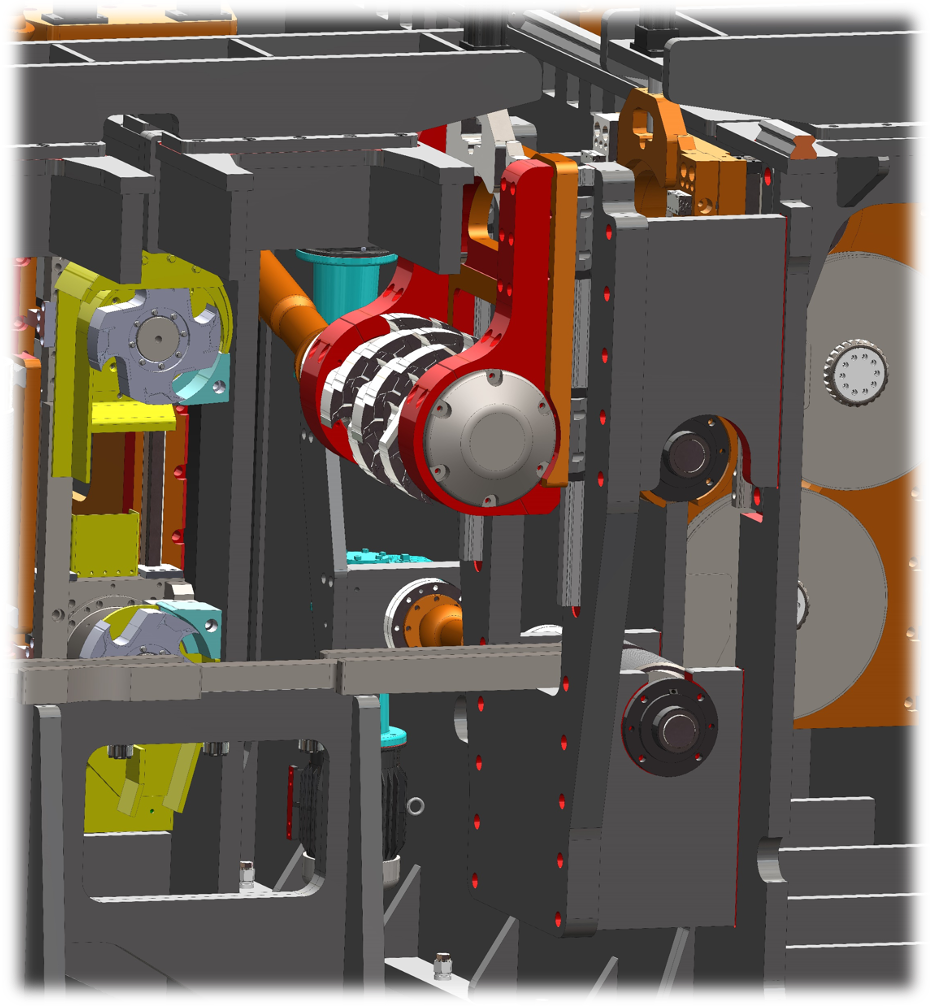

splined head and spiked press roll

- Chip Head Driven by Driveline directly coupled to Motor

- Spiked Press Roll to keep Block in position from Infeed

- Spiked press roll and splined bed roll are driven by individual 7.5HP

- motors through Worm Gearbox to eliminate surging while chipping

- Spiked Press Roll and splined bed roll direct driven with Drivelines

- Chip Head height adjustable for fine tuning to the bed plate

- Spiked Press Roll Hydraulicly controlled for force control as well as position control

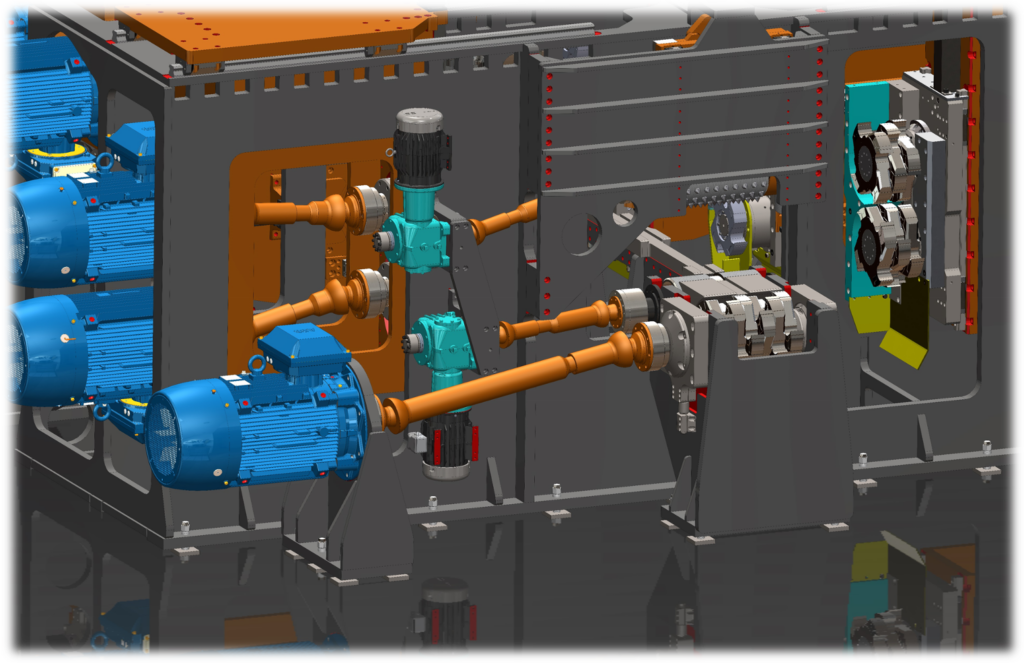

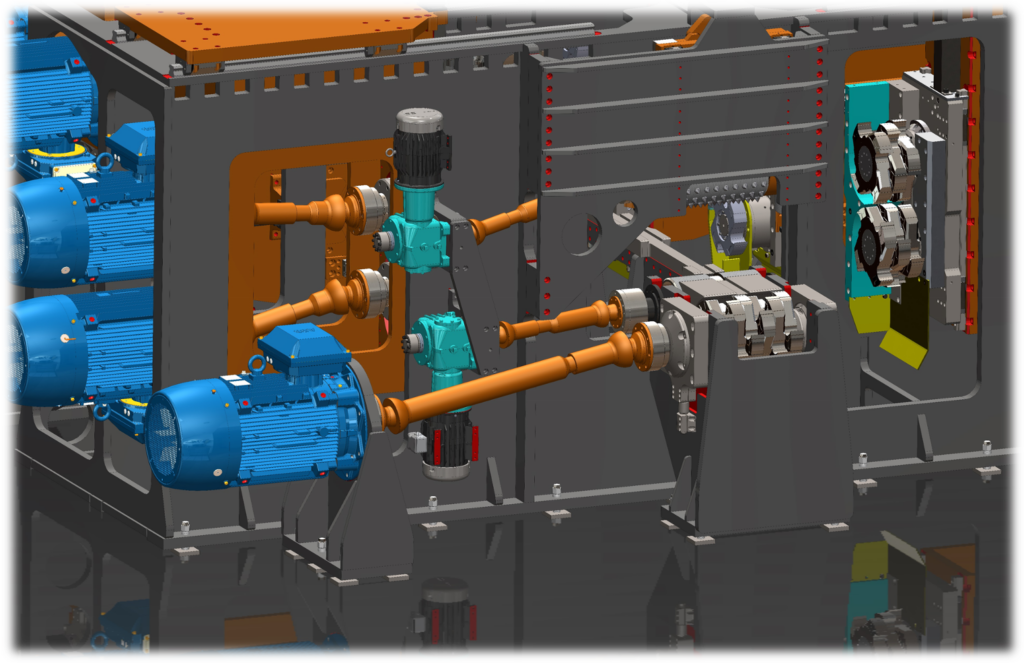

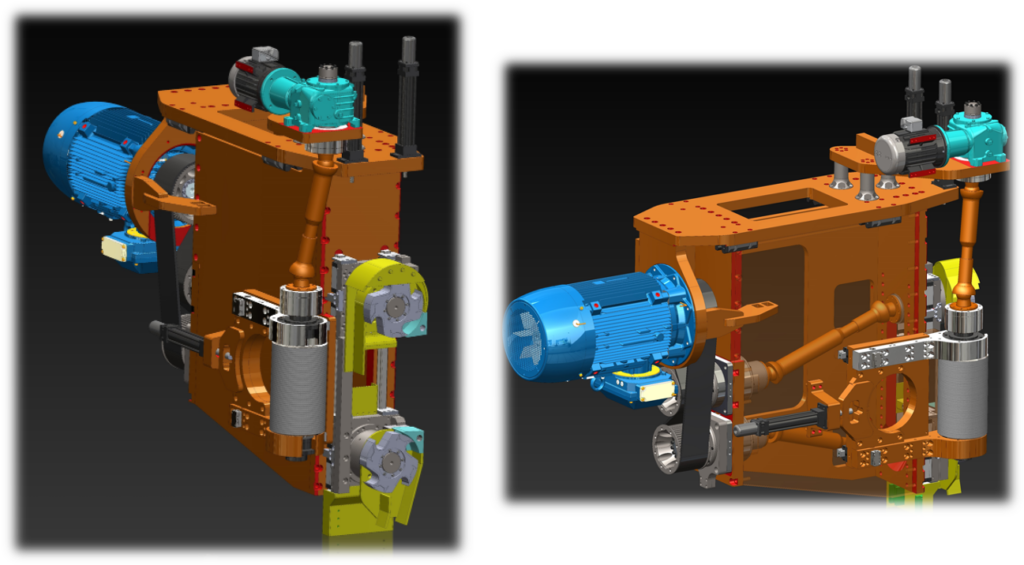

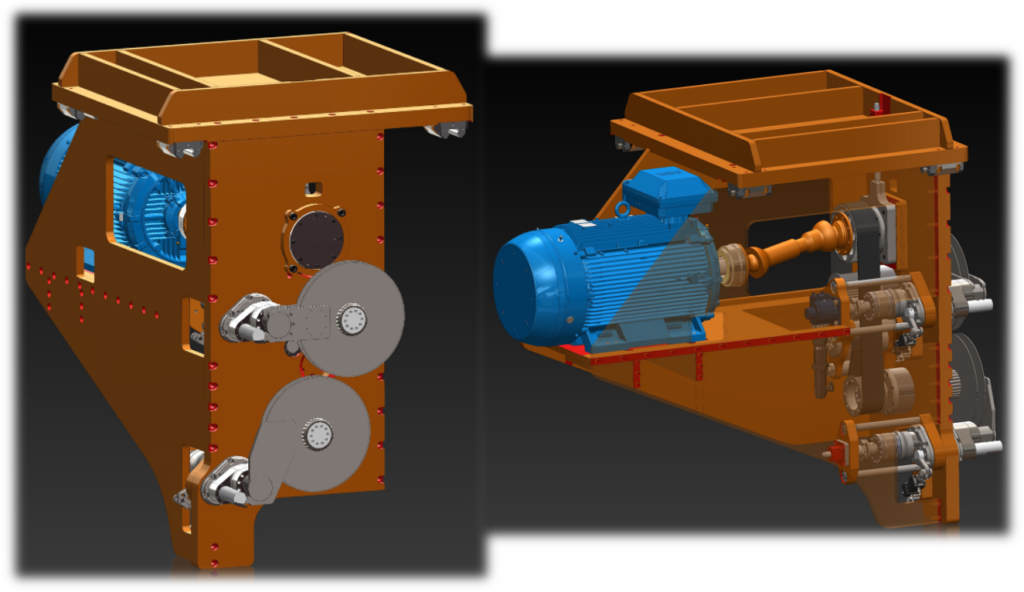

canter module

- Counter Rotating top and bottom heads equalize chipping forces

- Each head is directly coupled to motor with driveline

- Canter Heads set vertically to block thickness to equalize chipping forces

- Maintenance mode for easy access for knife changes and Maintenance

profiler module

- Top and bottom profiler heads independently adjust for different sideboard widths

- Vertically slewed side boards solutions are achievable

- Top and bottom heads driven by the same motor with drivelines

- Side rolls ride with profilers but independently adjust

- Side Rolls use same frame, roll and cylinders as press rolls

- Side Rolls independently driven by 7.5HP motor through worm gearbox for complete control of block

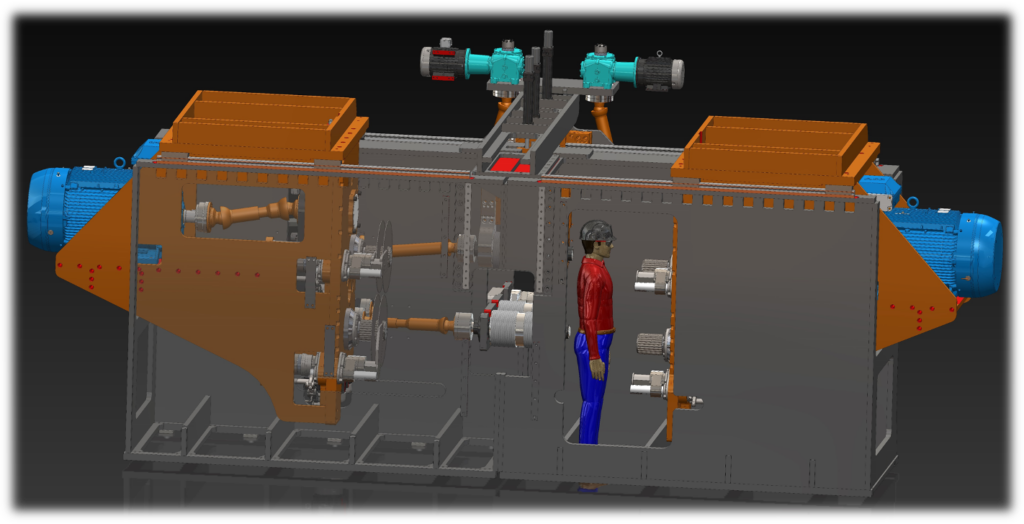

profiler module maintenance mode

Like the Canters, the Profilers move out to a maintenance position to allow easy access for knife changes and maintenance

Enter on the RH canter module to access both sides of the machine

Top Head Module

Top Head is Driveline Driven to reduce moving mass and set time

Uses same shaft and bearings as spline chipper and spline remover

Assembly is mounted to linear bearings and rails for rigid precise mounting

Carriage made from 4” and 2” steel plate for durability and longevity

double arbor quad sawbox

There are two moveable saw boxes that move instead of the conventional Fixed arbor moving guides configuration

This allows for a much more rigid arbor and guide design to achieve higher sawing speeds while increasing accuracy

Single motor for each side of the machine

Top arbor offset automatically adjusted to eliminate saw mismatch

Arbors can be configured as a twin or quad depending on installed guide arrangement

quad sawbox maintenance mode

Sawboxes move into maintenance position for easy access for saw changes and maintenance

Access point is through the RH SawBox Structure

spline remover

Spline Remover uses same shaft and bearings as Spline chipper and Top head

Spline remover is adjustable to allow fine tuning of final bottom face of cant

Drive line driven to keep motor away from debris and easy to access