HOTT ProDog

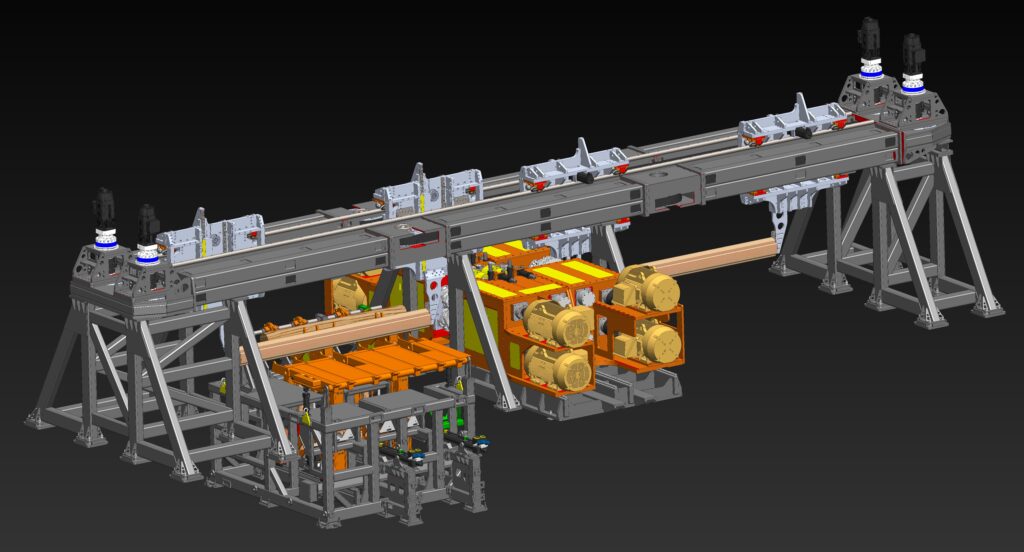

The ProDog (End Dogger System) is a complete primary breakdown solution that offers piece counts and gaps comparable to sharp chain style systems. Full rotation of logs gives the highest recovery possible. Our dual carriage ProDog system provides canting, double profiling and quad saw box in only 8.5’. As with all of our HOTT Technology systems, all critical components are located above the cutting tools and debris.

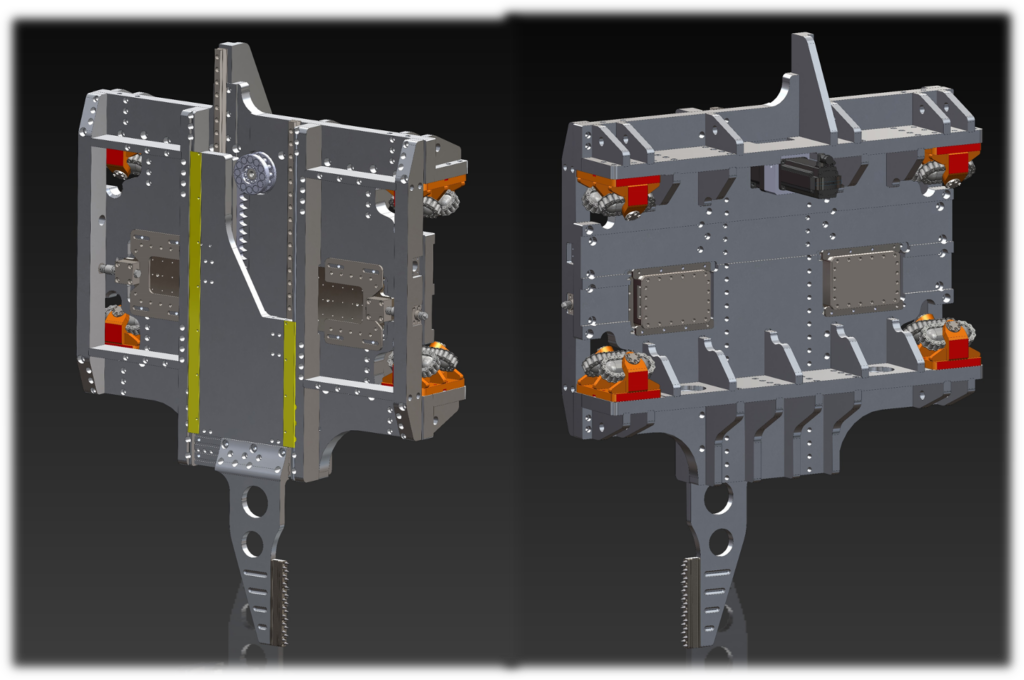

Carriages

- Carriages constructed out of 3”, 2.5” and 1.5” Thick 7075-T6 Aluminum (higher strength than a-36 steel at 1/3 of the weight)

- Carriages ride on Thomson Roller Roundway bearings for high speed and long life

- Carriages are driven by oversized 150mm wide timing belt with higher load ratings than conventional cables

- Dog arm utilizes Linear motion instead of a pivot to reduce complexity and required Piece gap

- All electric actuation of carriage travel and dog arm lift/lower

- Replaceable break-away dog arm

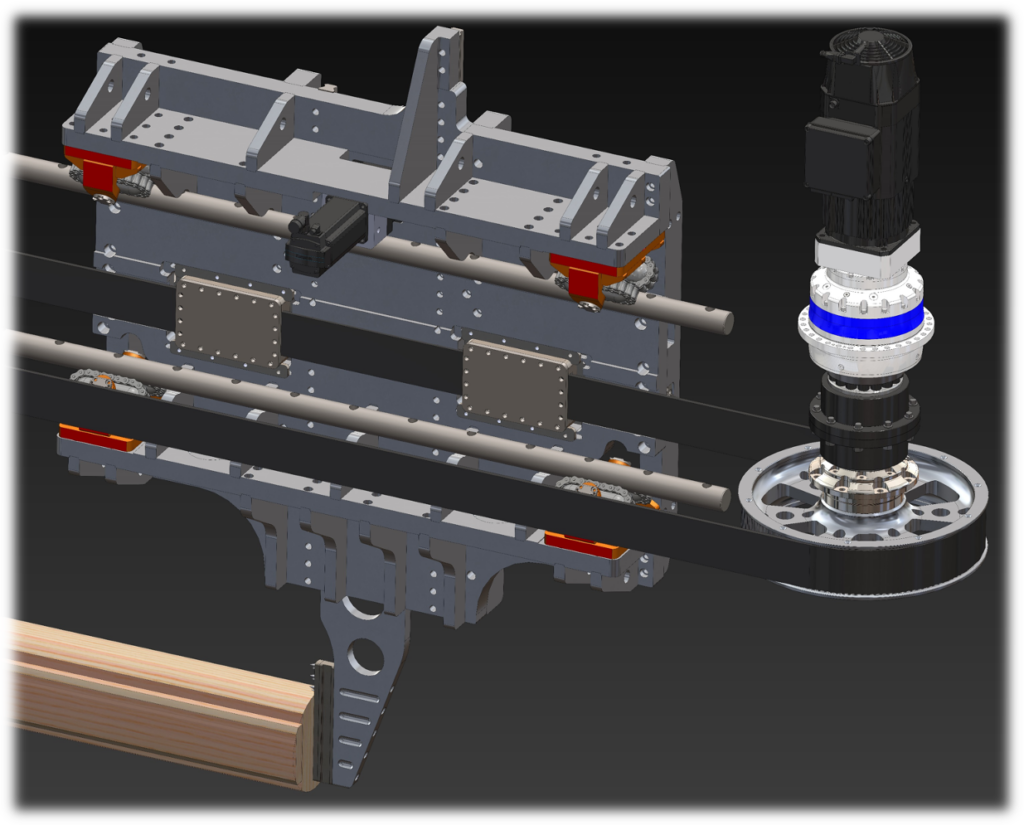

Carriage Drives

- Carriage drives use 150mm wide timing belts on edge for tight packaging and debris management

- Carriages have two clamping points in which the belts attach

- Each carriage is driven by a large servomotor and gearbox with low backlash (3 arc min or less)

- Drive configuration uses large spherical roller bearings with common parts between head and tail

- Belt tensioning done at carriage to allow head and tail to stay fixed

- Belts are a Polychain style with 20mm pitch, up from common 14mm

Carriage Beams

- Beams constructed of double stacked 8” x 10” x ½” HSS Tube and 3” solid steel plate

- Precision machined in one setup after fabrication Top and bottom

- Thomson Roundways bolt to a single 3” vertical plate

- Timing belts run inside of beam structure kept out of harms way

- Belt access points are intermittently cut into beam structure

- Support structure made from 6” x 10” x ½” hss tube and heavy plate

charging system

- Startup video showing slower than production speed

- Final scan of log done after log is clamped

- Final rotation and positioning (slew, skew, lift, tilt) done with log clamped exactly how it was scanned

- Scanning done offline; positioning done as log moves to centerline

- No rolls attempting to rotate and position unpredictable log surfaces

- Short overall footprint compared to sharp chain style system

- No rotation limitations from log instability on a sharp chain

- Typical 3% increase in recovery from log positioning accuracy

charging system

- Production Video

- This system runs 20 to 22 LPM

- Logs come in with consistent lumber line

- This is showing a single scan zone with geometric turners that use gravity to get the log horns up/down

- Lower piece count systems can use the scanner to pre scan and pre rotate in the turner arm

- Higher piece count systems can utilize a second scan zone to achieve the same full 360-degree rotation solutions

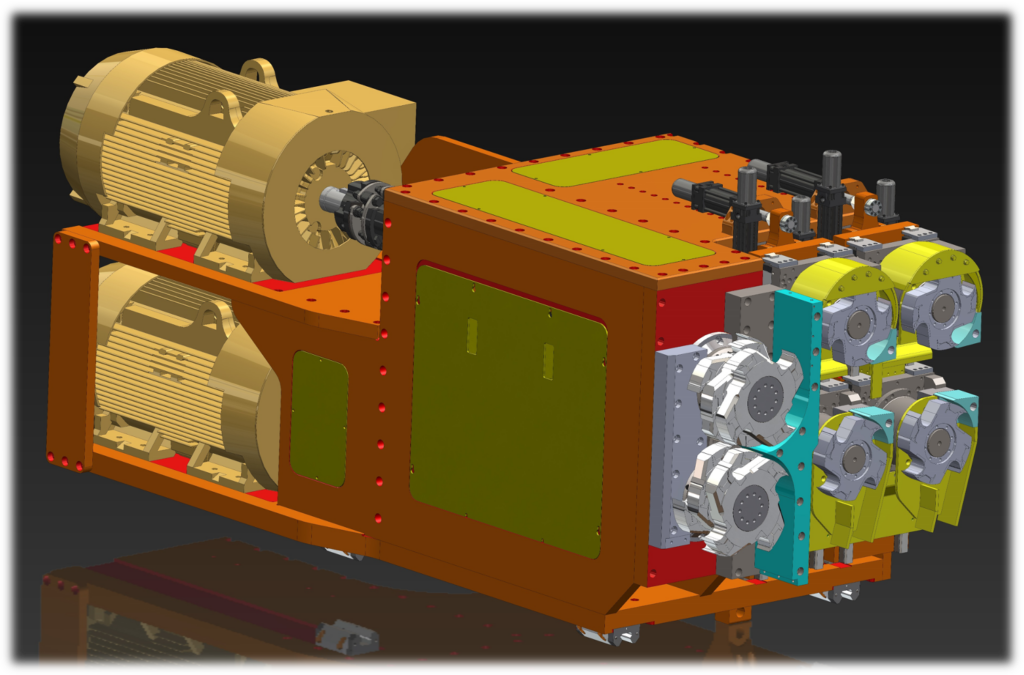

Canter Profiler Module

- Module constructed of 3”, 2” and 1.5” A36 steel plate

- Main carriage rides on 65mm ina linear bearings

- Canter heads counter rotate for equal chipping forces

- All top cutting tools driven by one motor

- All bottom cutting tools driven by one motor

- All cutting tools are driveline driven for simplicity

- All cutting tools use proven and common spindle assemblies

- Profiler tools are independently positioned for slewed sideboard solutions

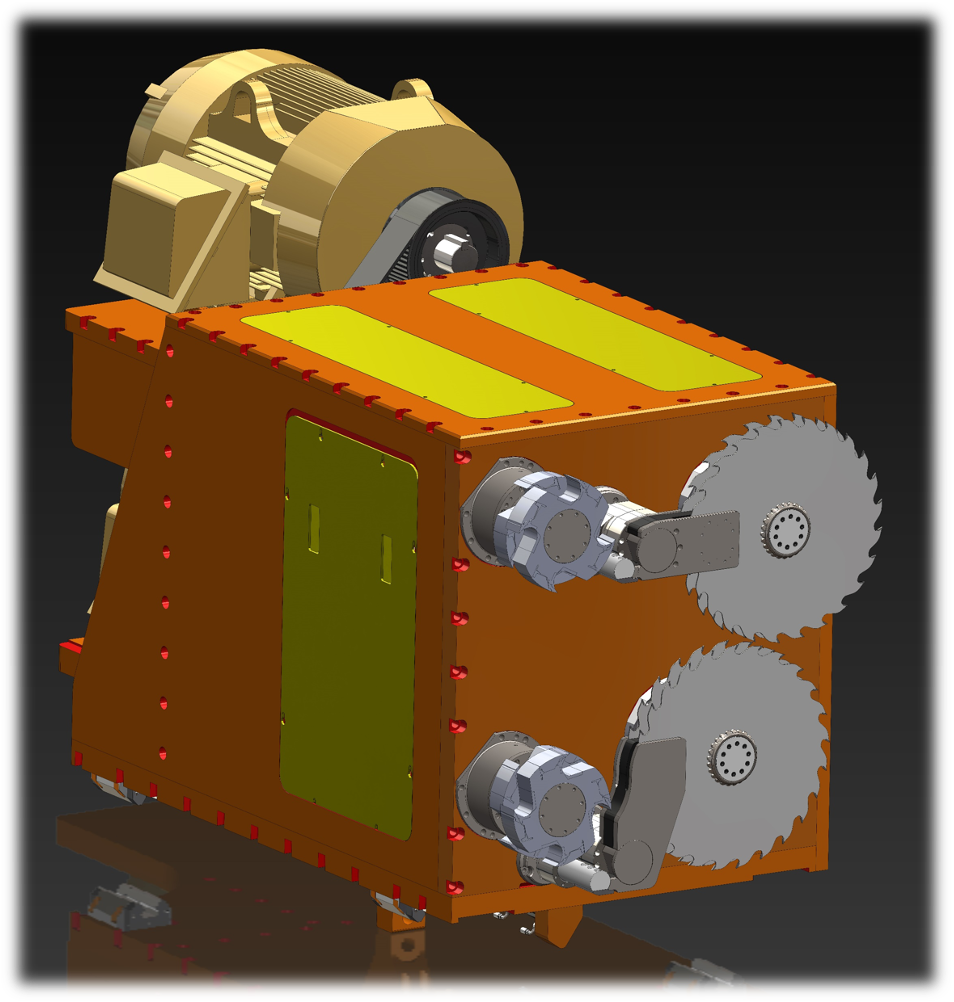

Quad Sawbox Module

- Module constructed of 3”, 2” and 1.5” A36 steel plate

- Main carriage rides on 65mm ina linear bearings

- All top cutting tools driven by one motor

- All bottom cutting tools driven by one motor

- All cutting tools are driveline driven for simplicity

- Top Arbor on the fly mismatch adjustment

- Top and bottom guides have knot buster to protect guides from log anomalies

- Log diameter is split between top and bottom saws, allowing higher recovery vs the competitor

5-Way Outfeed Dispatch

- Outfeed can separate to 5 different downstream locations

- Inertia separators below feedline divert boards/flitches to the desired location (Backline, Re-saw, Board Edger, Etc.)