HOTT ProSaw Systems

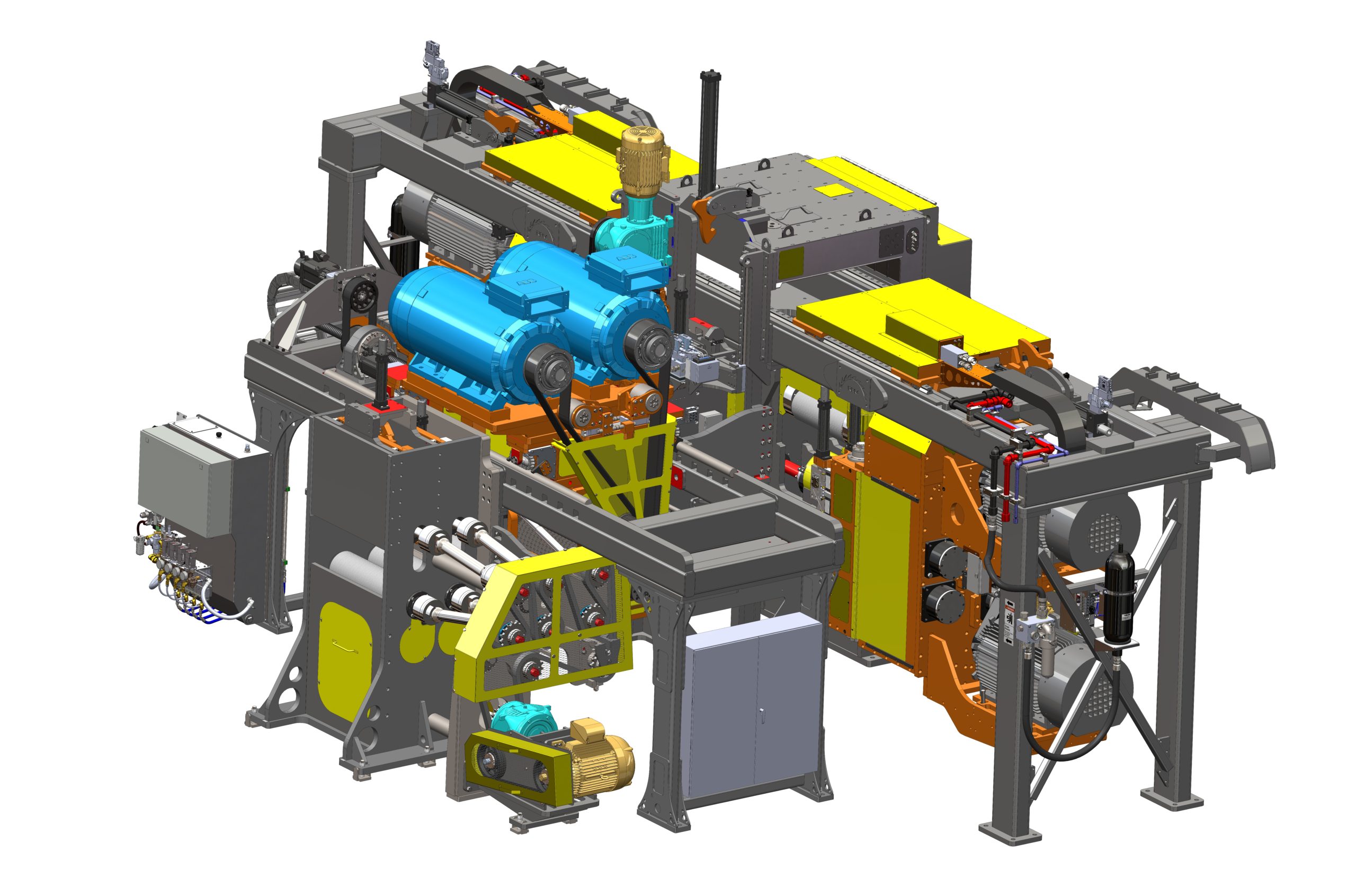

RPM’s HOTT ProSaw Systems are the most advanced secondary breakdown product in the sawmill industry. Our systems have been developed to solve many of the current issues that affect quality, maintenance and production performance. Our HOTT ProFormer works in sync with our HOTT ProScission to provide the most accurate curve profiling and curve sawing system in the industry. These two machine centers combine to produce an industry leading secondary breakdown solution. Our machine centers are manufactured with the highest quality craftsmanship and components with an attention to detail on reliability and precision. Our installations can be completed with decreased mill downtime and provide our customers with a much higher and faster return on their mill’s investment. If you want lower maintenance, better recovery, increased throughput and higher quality lumber with more reliability, RPM can provide proven results.

integrated pairing

- HOTT (Hanging-Over-the-Top) Technology

- Low to No Maintenance and Lower Overall Cost of Operation, including increased saw and saw guide life

- Higher Quality + Reduced Set Times + Smaller Target Sizes = More Throughput and Faster ROI

- Tightly coupled and precisely controlled with hydraulic Press Rolls allowing for reliable processing of shorter cants

- Easy machine access for saw and knife changes

- Entire line fits within 20′

INDIVIDUAL PRODUCT DETAIL

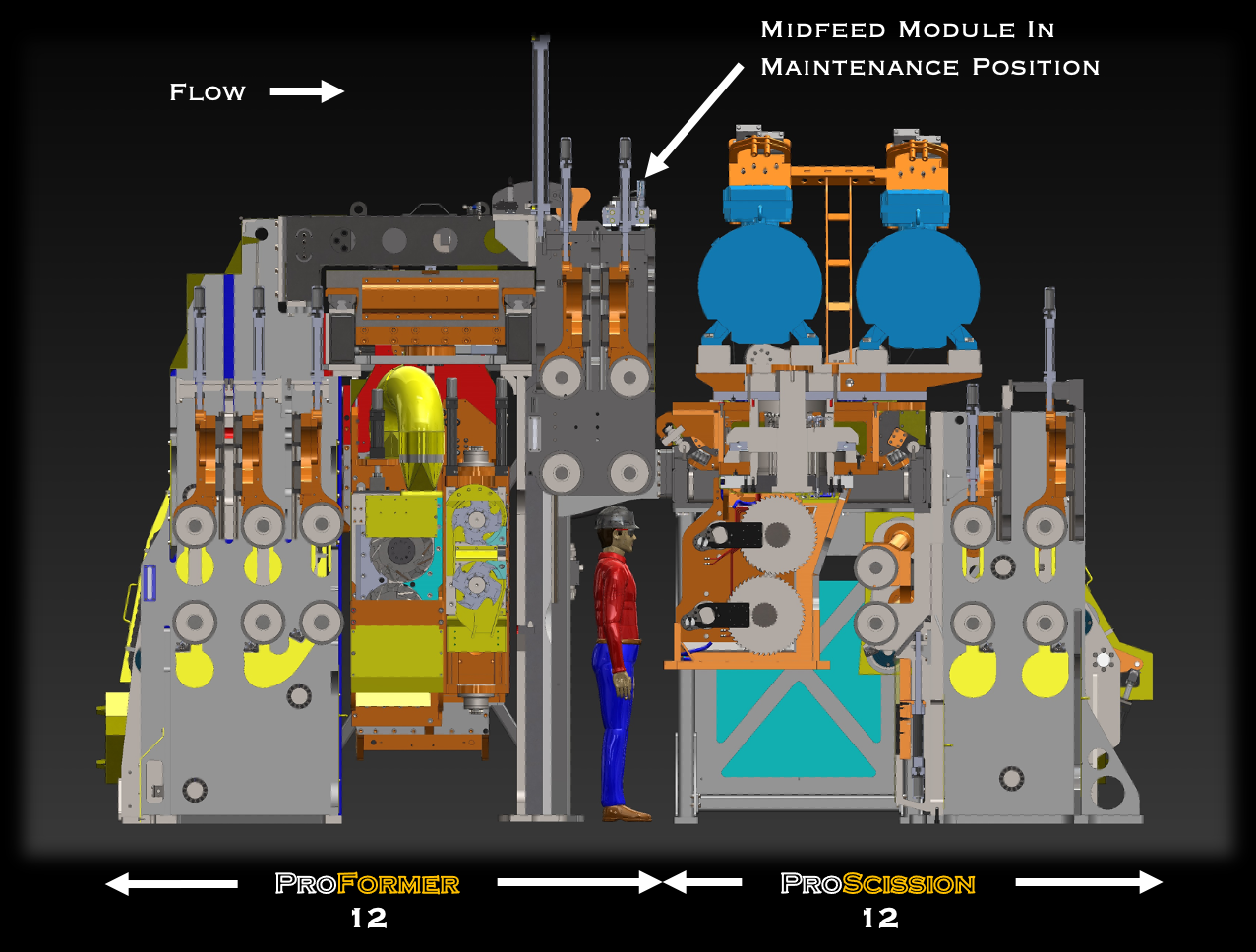

HOTT ProFormer

Installing a RPM Canter/Profiler will increase your mill’s potential capacity by removing the production bottle neck that often occurs at the edger. Precision hydraulic press rolls and vertical canter centerline sets provide industry leading cant stability and control. The revolutionary rigid design of the RPM HOTT ProFormer will improve lumber quality, reliability and overall mill flow, with easy machine access and reduced maintenance.

HOTT ProScission

Installing a RPM “Electric” Curve Sawing Gang will lower cost by increasing saw and saw guide life while producing quality lumber and higher yields. Electric actuators ensure near perfect motion control as well as on-the-fly arbor offset adjustment to minimize saw mismatch. The revolutionary design of the RPM HOTT ProScission minimizes maintenance requirements and maximizes machine uptime and production.